Fences rarely fail all at once, their performance declines gradually. A gate begins to drag. Latching the door becomes an effort as the door is not aligned. Panels loosen under wind load. Post tops hold moisture and discolor. Then corrosion appears around connection points. What starts as minor faults then lead to premature repair.

In many cases, the main materials of the fence are not the source for this failure. The weak link is the fence accessories: post caps that do not shed water, brackets that allow movement at rail-to-post connections, and hinges that are not rated for the gate’s. Because these parts are fixed at stress and exposure points of the fence their quality and installation needs to be flawless.

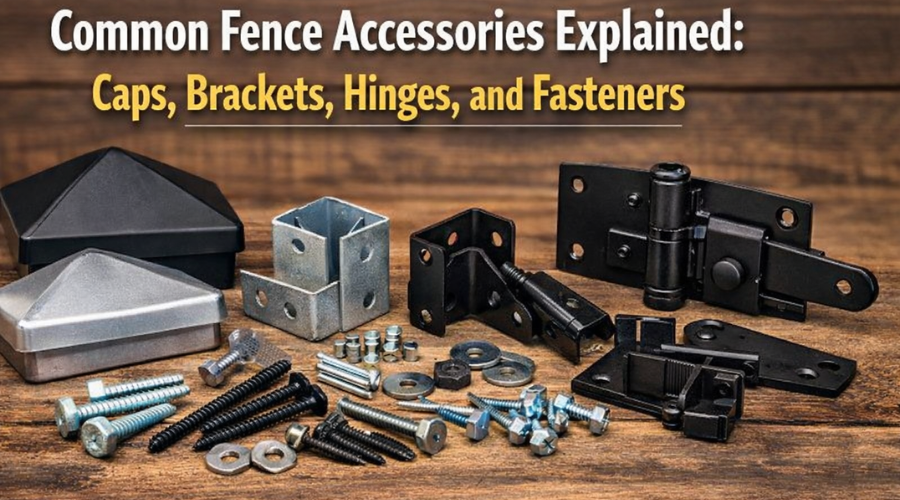

The solution is to specify fence accessories as a system. When caps, brackets, hinges, and fasteners are selected to match fence type, environment, and load requirements, the fence remains stable and free from corrosion. And that means less repairs. This blog explains what each accessory does, and how to choose durable options to maximize fence lifespan and performance.

The smartest purchases begin by considering the fence type and the environment. Wood fences are versatile and provide a variety of attachment styles for fastening fence accessories but the accessories need to be really corrosion-resistant. Vinyl fences look neat and clean, but their downside is that they crack easily when accessories are over-tightened. Chain link fence requires specialized custom fence fittings so generally available fence accessories tend to be useless in this situation. And metal panel fences demand compatible fasteners to prevent corrosion problems that spread.

Galvanized coatings resist rust well in many inland locations. Stainless steel fittings perform exceptionally well in agricultural land where exposure to salt, and minerals is frequent. Such fences are constantly exposed to sprinklers and fertilizers.

Powder coating improves appearance and adds protection, but cut edges and scratches must be respected.

If you are buying for multiple fencing projects, you need to procure consistent quality. A reliable fencing hardware supplier can help standardize sizes, finishes, and load ratings. If you manage installs at scale, wholesale fence accessories and bulk fence accessories reduce per-job variance. A reputable fence accessories supplier should provide clear specs, not vague promises.

Post caps have a dual purpose: they protect and they deliver a polished appearance. On wood, the post top is end grain, which absorbs water a lot. Caps prevent this absorption and stop the wood from swelling, and rotting due to moisture. On vinyl and metal, caps keep debris out and deliver a finished line that has a visual appeal.

Ensuring a flawless fit is the first priority in cap selection. And standard post sizes do not always equal real dimensions, especially after milling, swelling, or sleeve installation. Next, pick a material that matches your exposure. Copper and aluminum caps handle weather well. On the other hand, vinyl caps excel when you need perfect color continuity. Solar caps add visibility and curb appeal, but their longevity depends on battery quality and sun access.

Caps need to be attached according to the recommended method, which usually dpends on the cap type. The installation method can be through screws, adhesive, or friction fit. On wood, sealing the post top before capping adds a layer of protection that maximizes the life of the cap and the wood post.

Brackets and connectors are hardware that keep the fence panels aligned perfectly. They also distribute load when the fence is exposed to wind pressure. Their function is to keep fence rails from twisting, panels from racking, and corners from loosening during the windy weather. When a fence sways during strong winds, the root cause is often a weak bracket and not the fence post itself.

Start by identifying the connection: rail-to-post, panel-to-post, corner, end termination, or post-to-surface mounting. Once you have determined the nature of the connection, then make the material choice. Wood fences often benefit from robust rail brackets at high-stress zones, such as gates and long runs.

Vinyl and metal panel fences frequently require manufacturer-specific clips to deliver long-term service life and secure fit. Thickness and hole pattern matter because thin brackets flex and become loose since the hole becomes oval due to the constant movement and vibration of the post.

Installing brackets involves precision and attention to detail. Mark level lines, pre-drill where splitting is likely, and keep fasteners centered to avoid pull-out. Use corrosion-resistant hardware that matches bracket material. This fence accessory is prone to rusting. If you are unsure about the process, our easy installation tips blog can help you install brackets correctly

A gate is a moving lever, and hinges are the fulcrum. If hinges are undersized, the gate sags and the latch requires effort to lock. If hinges are well-matched, the gate movement is smooth and controlled, even in wind. This is why hinge selection is less about style and more about physics.

Strap and T-hinges spread load across the wood rails and suit traditional wood gates.

Butt hinges can look clean but demand accurate alignment and a stable frame.

Adjustable hinges are the problem-solvers when you need to fine-tune sag. A premium type of hinge is a self-closing hinge, but they must be rated for the gate weight and used with the right latch types.

Mount hinges to solid structure, not to weak pickets or thin trim. Use through-bolts when appropriate. Add an anti-sag kit when the gate is wide, heavy, or wind-exposed. The gate will confess every shortcut.

Fasteners are overlooked by many people because they are small parts that seem unimportant. But they are what ensure the stability of the fence and make it vibration-resistant against wind and safeguard it from rust. A fence can be beautifully built and still fail early if the fasteners rust, snap, or loosen.

Exterior screws deliver strong holding power and are much easier to maintain than nails.

Ring-shank nails are another variant that can be installed quickly but they are harder to adjust later.

Carriage bolts create clean, secure connections at hinges and critical brackets.

Lag screws, another kind of screw, are a perfect choice to handle heavy loads when installed with proper pilot holes.

Treated lumber can accelerate corrosion, so coatings and stainless steel grades of screws are vital to safeguard the fence from failing early.. In wet or coastal environments, stainless steel often wins on total cost. Another thing to consider is to prevent overdrive of fasteners into vinyl, as it can crack or deform the vinyl. Attention to detail here will prevent costly rework later.

The fastest way to reduce mistakes is to match accessory choices to fence material and typical failure points. Wood needs rot and rust defense. Vinyl needs controlled pressure and system-specific parts. Chain link relies on tension hardware. Metal fences demand corrosion-compatible fasteners and hinges that handle weight cleanly. If you source through a fencing hardware supplier, bring this map and align finishes and grades across the entire job. When purchasing bulk fence accessories, standardize sizes to reduce on-site improvisation.

Wood Metal or wood caps for water shedding Rail brackets at stress points; corner reinforcement Strap, T, or adjustable hinges for sag control Exterior-rated screws either hot-dip galvanized or stainless

Vinyl/PVC Matching vinyl caps for clean finish Manufacturer-specific clips and brackets Self-closing or adjustable hinges rated for gate weight Corrosion-resistant screws; avoid overtightening

Chain link Post caps, loop caps, and rail ends Brace bands, tension bands, line rail fittings Gate hinges sized for frame diameter Bolts and nuts should be galvanized

Aluminum/steel Metal caps, often press-fit Purpose-built panel brackets; post bases for mounts Adjustable or self-closing hinges for heavy use Stainless or compatible coated fasteners; protect cut edges

Fence accessories are not optional extras. They control the water absorption, and rate of corrosion. Caps protect the most vulnerable wood surface. Brackets and connectors keep rails and panels stable and shake proof under wind and time. While hinges determine whether the fence gate feels effortless or becomes an annoyance to open and close. Fasteners hold the entire promise together, quietly, until they do not.

When choosing fence hardware your decision making priority should start by environment and fence material first, and aesthetics should be secodary. Invest in corrosion resistance where water and chemicals are present. Use rated hinges and through-fastened connections where loads concentrate. If you are scaling projects, work with a fence accessories manufacturer that publishes clear specifications and testing data.

Fences rarely fail all at once, their performance declines gradually

READ FULLA chain link fence may look like nothing more than steel wire stitched into diamonds, but once yo

READ FULLImagine stepping outside in 2025: what do you see? You see smaller yards. You s

READ FULL